Environmental management and rehabilitation at Lightning Ridge

Areas disturbed by opal prospecting and mining activities should be returned to a condition that is safe, stable and self-sustaining.

Overview

It is essential that rehabilitation is undertaken so that areas disturbed by opal prospecting and mining activities are returned to a condition that is safe, stable and self-sustaining.

The final condition of the land following the completion of prospecting or mining should be as good or better than the state of the land prior to opal prospecting or mining activities. This allows the land to be managed for future generations and sustainable future land uses such as agriculture, native environments or future resource activities.

Land disturbed by opal prospecting and mining activities is considered to be rehabilitated when it can be demonstrated that it is safe, stable, does not cause environmental harm, and is able to sustain post-mining land use.

**NOTE: Title holders are advised to read the specific conditions relating to their opal prospecting area or mineral claim to ensure they are complying with the title conditions.

Progressive rehabilitation

Progressive rehabilitation will minimise the risks of environmental impacts and reduce cumulative areas of disturbed lands. A benefit of progressive rehabilitation is that it results in a significant reduction in the amount of rehabilitation when opal mining is completed.

It is recommended that the mineral claim holder keep records of progressive rehabilitation undertaken.

Suggested records may include:

- Photographs of:

- the claim area prior to commencement of opal prospecting or mining operations

- disturbance caused by opal prospecting or mining operations

- progressive rehabilitation undertaken (i.e. photos of shafts and auger holes rehabilitated in accordance with the above rehabilitation standards) including dates

- Records of the salvage of all rehabilitation resources including suitable capping materials, topsoils / subsoils, seeds, habitat structures (e.g. tree hollows and rocks) for use in rehabilitation

- Records of any environmental incident reports, including any corrective or preventative action taken

- Records of maintenance activities undertaken on rehabilitation areas

It is also good practice to take a GPS reading of the four corner pegs of the mineral claim and pass this information onto the Regulator. An Inspector can then determine that rehabilitation has taken place within the exact boundary of your claim following an expiry or cancellation of the mineral claim. Always have your mineral claim marked as required by legislation. This information will be helpful if a dispute arises or if there is a query as to the location of the boundaries of the mineral claim.

Rehabilitation standards expected for shafts, auger holes and trenches are detailed below.

Topsoil Management

Topsoil is a valuable resource at Lightning Ridge in the rehabilitation process. It is important to remove the topsoil prior to commencing mining operations and stockpile to the side for later respread across the completed operation. The use of topsoil allows vegetation to re-establish quickly and so reduces erosion potential.

Mullock must not be spread across the final landform as this has the potential to inhibit vegetation from re-establishing and so may delay the return of security held by the Department. Mullock must be stockpiled separately to topsoil.

Vegetation clearing and surface disturbance

When drilling or undertaking mining activities, the following or similar measures should be used to minimise the area and duration of disturbance to land and vegetation:

- design and operate excavations to minimise the risks associated with overflow or spill events

- consider seasonal influences such as rainfall before excavating or establishing a site

- construct drill pads no larger than necessary to safely accommodate the drilling rigs and ancillary equipment.

The mineral claim holder should note that the felling of trees, stripping bark or cutting timber on the mineral claim requires the landholder’s consent.

To minimise the area of disturbance to vegetation and fauna, the following or similar measures should be used:

- avoid disturbing large and/or mature trees

- avoid disturbing habitat trees and hollow bearing trees

- select specific trees to be cleared and avoid causing damage to surrounding vegetation

- avoid vegetation removal in windbreaks and shelter belts

- where practical, leave the rootstock intact to promote regeneration and regrowth

- only clear White Cypress (Callitris glaucophylla), Black Cypress (Callitris endlicheri) and Mulga (Acacia aneura) species where the trunk diameter is less than 200 mm (measured at a height of one metre from the ground).

- Retain all cleared vegetation in stockpiles for use in rehabilitation. Stockpile vegetation should not be burnt.

At the conclusion of mining, cleared vegetation should be respread over the rehabilitated landform to assist with minimising erosion, moisture retention and providing habitat features for fauna.

The mineral claim holder should note that the clearing of native vegetation ordinarily requires approval under the Local Land Services Act 2013, however the Act allows clearing for allowable activities. Clearing undertaken for allowable activities on a landholding must only be carried out by, or on behalf of, the landholder. Further information can be obtained from the Local Land Services, North West Region.

Fauna protection

Vegetation clearing and surface disturbance should be conducted in a manner so as not to cause danger to fauna. The following or similar measures should be used where necessary:

- the installation of temporary fencing around the mineral claim and work sites

- preventing fauna from accessing open and unattended auger holes and mine shafts.

Threatened flora and fauna

Threatened species, populations and ecological communities are protected by the Biodiversity Conservation Act 2016 and Part 7A of the Fisheries Management Act 1994.

All known threatened species, populations, or ecological communities located inside the disturbance area should be noted and appropriate measures put in place to prevent harm. This could include demarcation with flagging tape or fencing with adequate curtilage.

Waste management

The mineral claim holder should ensure that all wastes (including drilling by-products contaminated by chemicals, contaminated residues, chemicals, oils or fuels) are collected, segregated and securely deposited in properly constructed containers and disposed of at a regulated waste management or recycling facility.

The Protection of the Environment Operations Act 1997 regulates the disposal of waste. It is illegal to deposit waste, as defined by the Waste Classification Guidelines (EPA, 2014), on land, unless it is an appropriately licensed waste facility, or the material is subject to an exemption issued in relation to the Protection of the Environment Operations (Waste) Regulation 2014.

Any material that may be classified as a waste under the Protection of the Environment Operations Act 1997 must be classified under the Waste Classification Guidelines (EPA, 2014) and disposed of at an appropriately licensed facility.

Use of chemicals, fuels and lubricants

The mineral claim holder should refer to the AS 1940-2004 – The Storage and Handling of Flammable and Combustible Liquids: Section 2 Minor Storage when managing all flammable and combustible liquids, excluding those contained within plant and equipment. The mineral claim holder may be required to comply with additional obligations regarding potential pollutants under work health and safety legislation (e.g. for the management of spills).

Water

If the mineral claim holder must not use water artificially conserved on that land without the consent of the landholder.

The mineral claim holder should have a clear understanding of the groundwater and surface water sources which may be impacted by the proposed mining activities.

The mineral claim holder should implement all practicable measures to minimise any:

- harm or pollution to surface water resources

- contamination or cross-connection of aquifers or groundwater sources, including through the use of suitable drilling techniques and fluids

- depressurisation of aquifers or groundwater sources as a result of water moving from one aquifer or groundwater source to another, or water being removed from an aquifer or groundwater source (including changes to surface water flows where there is connectivity between surface and groundwater systems).

Weeds, pest animals and diseases

Opal prospecting and mining activities should be conducted in a manner so as to minimise the spread of weeds, pest animals and animal and plant diseases. A ‘come clean — go clean’ protocol should be implemented when moving from property to property to ensure the mineral claim area is kept free of disease, soil pathogens, seeds, weeds and pest animals.

The following or similar measures should be used:

- ensuring that any soil and material imported into the mineral claim area is free of disease, soil pathogens, seeds and weeds

- thoroughly inspecting and cleaning machinery, vehicles, equipment and work boots prior to moving to a new property.

Land access

Refer to the Access Management Plan (AMP) for the property (if any) on which the mineral claim is held and ensure that you are aware of where you may mine. A copy of AMPs is available from the Lightning Ridge office of the Resources Regulator. The graphic plan attached to the AMP identifies areas where restrictions apply.

You should ensure you are aware of any existing improvements on the land. Things such as roads, tracks, drainage channels, contour banks, tanks, dams, grids and fencing are required by the landholder to manage the property.

Rights of way (roads and tracks)

A holder of a mineral claim is entitled to a right of way between the claim and a public road. You should, wherever possible, follow the route of any existing roads or tracks, and you must comply with the provisions of any access management plan for the property on which your mineral claim is held.

The mineral claim holder must ensure that they place substantial gates or grids (or if the landholder of the land requires you to do so) wherever fences are intersected by a right of way.

The placing of any gates and grids must comply with the requirements of the Mining Act 1992 and its regulation.

Culture and heritage

Aboriginal heritage

Aboriginal culture and heritage are legally protected in NSW.

Under the National Parks and Wildlife Act 1974, it is an offence to harm (destroy, deface or damage) or desecrate and Aboriginal object or Aboriginal place, or in relation to an object, move the object from the land on which it has been situated.

Penalties exist for anyone who knowingly or blatantly takes or collects Aboriginal artefacts.

If you find an Aboriginal artefact, you must leave it where it is and report the artefact and its location to Heritage NSW. Even if you believe the artefact is in danger of being damaged the best thing to do is leave it alone and report it immediately.

An Aboriginal object is defined under the National Parks and Wildlife Act 1974 as:

any deposit, object or material evidence (not being a handicraft made for sale) relating to the Aboriginal habitation of the area that comprises New South Wales, being habitation before or concurrent with (or both) the occupation of that area by persons of non-Aboriginal extraction, and includes Aboriginal remains.

Further information regarding Aboriginal cultural heritage can be found on the Heritage NSW website: https://www.heritage.nsw.gov.au/about-our-heritage/aboriginal-cultural-heritage/

Other heritage places and items of heritage significance

The mineral claim holder should avoid any impacts to an item of heritage significance. An item means a place, building, work, relic, moveable object or precinct. The presence of an item of heritage significance can be identified by checking the following registers and instruments:

* World Heritage List

* Commonwealth Heritage List

* National Heritage List

* State Heritage Register

* relevant environmental planning instruments, such as a local council’s environmental plan.

All known items of heritage significance located within the disturbance area should be noted and appropriate measures put in place to prevent harm. This could include demarcation with flagging tape or fencing.

Rehabilitation Standards

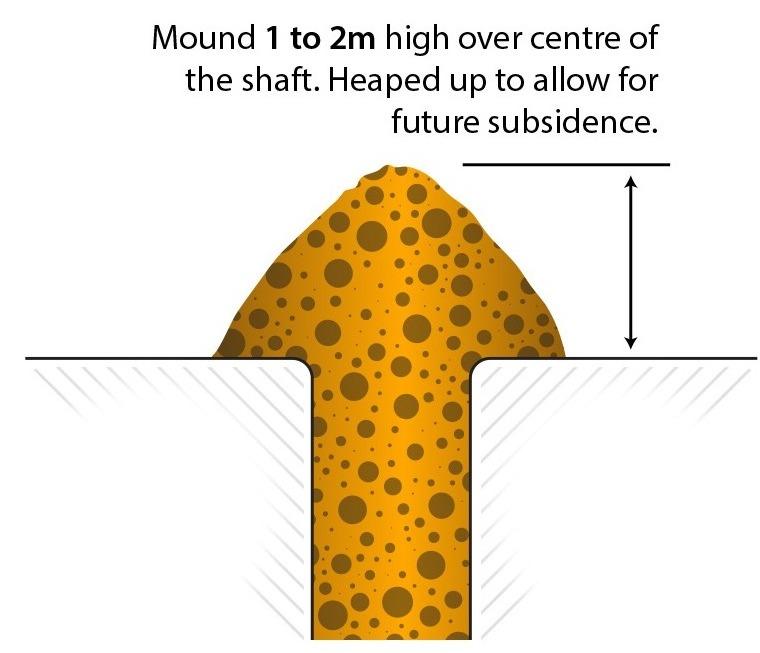

Rehabilitation Standards for Mine Shafts

At the conclusion of prospecting or mining, and prior to the expiry, of a mineral claim, the following is required to achieve good practice rehabilitation of mine shafts:

- All mine shafts on the mineral claim are to be backfilled with mullock. The mullock should be heaped over the centre of the shaft at a height of no greater than one to two metres.

- No excess mullock is to be redistributed over the site. Mullock not used for the purposes of backfilling shafts must be removed from the site and taken to a designated mullock dump.

- Stored topsoil and cleared vegetation is to be redistributed across disturbed areas of the claim.

Failure to rehabilitate to these standards may result in a mineral claim holder’s security deposit being forfeited.

Figure 1: Diagram of rehabilitated mine shaft

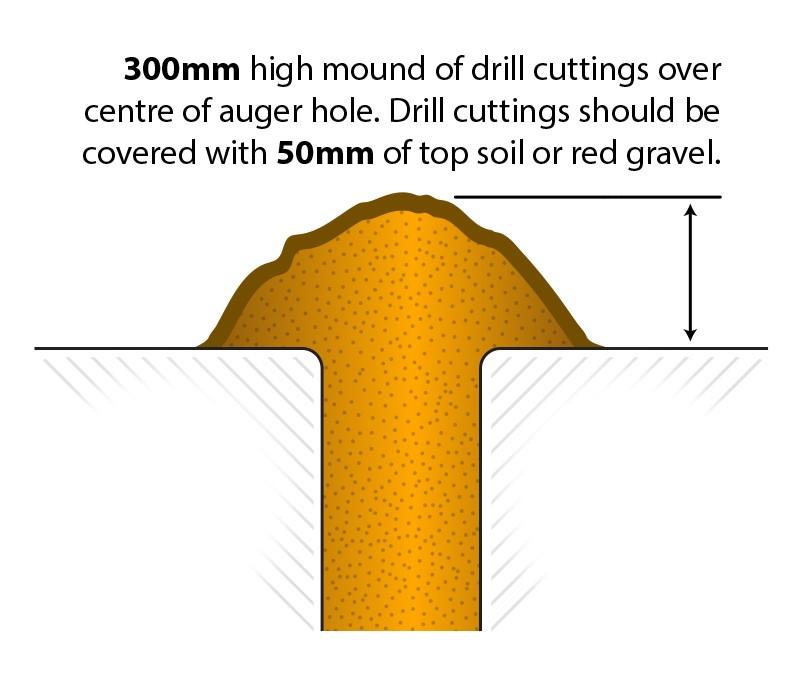

Rehabilitation Standards for Auger Holes

At the conclusion of prospecting or mining, and prior to the expiry, of a mineral claim, the following is required to achieve good practice rehabilitation of auger holes:

- Auger holes must be completely backfilled with no obstructions.

- Linked auger holes running into mine workings must be backfilled with mullock.

- The site should be cleaned to leave a circle of drill cuttings no more than one metre in diameter with a central mound over the auger hole of approximately 300mm high.

- Drill cuttings should be covered with approximately 50mm of red gravel.

- No excess mullock is to be redistributed over the site. Mullock not used for the purpose of backfilling auger holes must be removed from the site and taken to a designated mullock dump.

Figure 2: Diagram of rehabilitated auger hole

Rehabilitation Standards for Trenches

At the conclusion of prospecting or mining, and prior to the expiry, of a mineral claim, the following is required to achieve good practice rehabilitation of open cut disturbances:

- Trenches must be completely backfilled with no obstructions to surface water flow.

- The trench must be backfilled using the excess mullock and subsoil with topsoil respread over the top.

- No excess mullock is to be redistributed over the site. Mullock not used for the purpose of backfilling must be removed from the site and taken to a designated mullock dump.

Vegetation that was cleared and stockpiled prior to mining activities must be returned to the area to assist with revegetation, moisture retention and habitat features.