Ottery Mine

The Ottery Arsenic and Tin Mine (Ottery Mine) is located 8km northeast of Emmaville, NSW. The Glen Smelting Tailings Emplacement at Tent Hill (Tent Hill) is located 5km northeast of Emmaville, NSW. Both sites are the source of substantial concern due to them being significant point sources of arsenic as well as acid and metalliferous drainage issues.

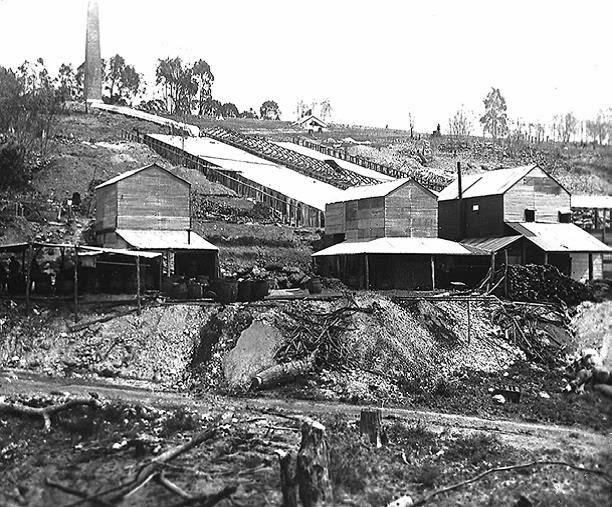

Ottery (pictured circa 1922), was worked from 1882 until 1957, being one the first tin and arsenic mines in the Emmaville district. Ore was mined, crushed and partly processed in furnaces at Ottery prior to smelting at Tent Hill. Given its age, Ottery has important historical features with significant conservation and heritage value.

Historical mining and processing activities at Ottery and Tent Hill have left behind residual mining wastes such as, waste rock dumps, tailings storage facilities, and a slimes dump. There are also arsenic salts coating the historic Ottery refinery. Residual mining wastes act as contaminant point sources for the generation and release of acid and metalliferous drainage (AMD) into the downstream environment.

Ottery Mine is the oldest principal ore refinery in Australia and listed on the State Heritage Register under the NSW Heritage Act 1977. As such the site attracts many visitors.

Various investigations were undertaken at Ottery over the past 30 years, with some remediation work also completed. The most recent rehabilitation works were undertaken during the 1990s.

Although previous rehabilitation has been undertaken the site remains one of the highest risk sites on the Derelict Mines Program database due to offsite environmental impacts and various open shafts.

Current Site Description

Much of the mine infrastructure remains at Ottery, though in a state of disrepair, including the former refinery, calciner, kilns, arsenic chambers and chimney stack. This infrastructure has been fenced off from the main footpaths, with signage erected to inform visitors of the cultural and heritage value of the workings.

Arsenic condensates and salt efflorescence from the former refinery process is evident as white/pink residue on the surface of brickwork in the arsenic chambers, calciner and refinery furnace.

Several adits and former mine shafts are present throughout Ottery mine site. Voids created by open cutting mining are present in the southern part of the site. Four main waste rock dumps, as well as a slimes dump and tailings storage facility also remain on site..

Tent Hill was the principal smelting site for Ottery and is located approximately 2.5 kilometres to the south. Remains of the smelting operation include two tailings dams and a minor scatter of bricks and concrete where the smelter stood. A more recent tin mining operation is located adjacent to the smelter site where only a tailings dam and three water dams remain.

Rehabilitation Works

In total, mining operations at Ottery produced approximately 2,000 tonnes of arsenic trioxide and approximately 2,700 tonnes of tin concentrate.

Selective surficial rehabilitation works were undertaken at Ottery in the 1990s that included:

- Reshaping of mullock (waste rock) dumps

- The installation of fencing and signage around the arsenic treatment plant

- Partial covering of the slimes dump

- Minor repairs to the dam wall adjacent to the Ottery tailings storage facility

- Installation of safety mesh over mine shafts and stopes

- Revegetation trials on a graded slope below the arsenic treatment plant.

No rehabilitation works have been undertaken at Tent Hill.

Acid and Metalliferous Drainage (AMD)

AMD is formed when pyrite, and iron sulphide, is exposed and reacts with air and water to form sulfuric acid and dissolved iron. Some or all of this iron can precipitate to form the red, orange or yellow sediments in the bottom of streams containing mine drainage. The acid runoff further dissolves heavy metals such as copper, lead, mercury into ground or surface water. The relocation of waste materials to one catchment (Ottery Mine voids) will therefore improve environmental health though the reduction of AMD generation and also reduce the public safety risk associated with the void spaces.

Future planned works

The proposed Ottery Mine Major Remediation Project (The Project) will be funded by the Derelict Mines Program and is estimated to cost around $2.5 million.

To ensure that the Ottery Mine does not present a significant risk to public health, work is being scheduled to reduce any potential contact with arsenic salts or arsenic rich drainage from the site, this has the potential for very high to extreme human health consequences.

Work will also occur at the Tent Hill which contains two eroding tailings emplacements. These works will significantly alleviate any potential elevated arsenic concentrations, thus reducing a downstream risk.

The Project comprises a series of works to reduce significant risks (85% overall reduction in acidity discharge load this equates to approximately 35 tonnes of sulfuric acid per year), including:

- Relocating tailings containing high acidity and metal loads (Tent Hill Southwest Dam 2 & Ottery Tailings Storage Facilities) to a secure storage location within Ottery Mine voids

- Relocating Slimes dump material to the Ottery Mine voids

- Relocating selected waste rock dumps to Ottery Mine voids

- Geochemical stabilisation of all material prior to relocation, treatments to be used may be:

- Blending waste with limestone

- Compaction of material placed in the voids to minimise air entry

- Moisture control to minimise seepage

- Waste cells will be designed to prevent water ingress

Key aspects of the cultural heritage value of the Ottery Mine infrastructure will be maintained, including access to the walking trail around the main processing area.

Mine History and Heritage Value

The New England Region was explored by Europeans between 1817 and 1830, with settlement by pastoralists beginning soon after. Settlement of the region began to expand in the 1850s when precious mineral lodes were discovered leading to the expansion of what are now major centres in the region, including Glen Innes.

The town of Vegetable Creek, later Emmaville, thrived with the discovery of a tin lode in 1872 which lead to the development of numerous mines in the area including the Ottery Mine, which was one of the first underground mines in the Emmaville district.

The tin lode at Ottery was discovered in 1875 and the mine began production in 1882, operating solely as a tin mine until 1920. After ore was extracted it was transported and crushed at Tent Hill for processing. The mine was then used to produce and refine arsenic and operated in this capacity from 1929 to 1936. The Ottery mine continued to be worked for tin until about 1957.

The Ottery Mine is listed under both the State Heritage Register and the Glen Innes Severn LEP. The curtilage of the State Heritage register listing is shown below.

The two heritage listings and previous investigations show that the Ottery Mine is a state significant heritage location (hence its State Heritage Register listing).

Tent Hill is not listed on any heritage lists or register; however it is referred to in the majority of documents associated with the Ottery Mine. Apart from the tailings dams, there are no real remnants of the processing infrastructure remaining on site.

The Ottery Mine commenced operations in 1882 making it one of the first tin mines in the district of Emmaville. From 1882 to 1906 tin ore extracted from the mine was transported to the nearby Tent Hill processing area where it was crushed and smelted into 50 pound ingots of tin concentrate. As the sulphide content of the tin ore increased over time, the process was altered with the ore first being calcined in furnaces at Ottery prior to transport to the smelter Tent Hill.

From 1920 to 1929, processing for arsenic ore was undertaken at Ottery. Arsenic ore was calcined in furnaces, volatilising the arsenic. Through a condensation process in a series of chambers, purified white arsenic trioxide (As2O3) was precipitated. In 1925, the arsenic ore became rich in tin as well as arsenic, so further crushing and extraction of tin was undertaken.

From 1931 to 1936, the mine was inactive and the facilities fell into disrepair. Whilst mining operations ceased in 1936, they recommenced for one year in 1956 to reprocess the remains of the calcined waste dump.